Home › Forums › NOE Forums › NOE Archive › Historical Archive › Using NOE Moulds › Casting and Reloading › Mould temp and cast size?

- This topic is empty.

-

CreatorTopic

-

2014-06-06 at 17:25 #487328

SwedeNelson

Keymaster::Had some time to cast with a 460483 378Gr. RN mould

This has been a great bullet and a fun one to load and shoot

Preheated mould to about 280F and cast one pour.

Discarded first pour.

Cast two more pour’s at 280F to 295F

Measured all ten:

.46025

.46020

.46040

.46035

.46040

.46020

.46050

.46070

.46035

.46045Ran mould temperature up to 340F to 360F and got frosty bullets

Cast two more pour’s

Measured all ten:

.45960

.45980

.46005

.45985

.45970

.45970

.45940

.45920

.45890

.45860Temperature differences are a lot more apparent in a bigger bullet

Just something to ponderBullet maker, maker

Al Nelson -

CreatorTopic

-

AuthorReplies

-

2014-06-20 at 01:18 #491225

thomasgarcia1

Participant2014-06-20 at 07:02 #4912262014-06-20 at 14:48 #491227SwedeNelson

Keymaster::The mould block was a 460483 378Gr. RN 5 cavity block

Pot temperature was 700F, I have our “shop Pot” set at that and keep it there.

The mould block temperature was checked using one of our digital thermometers

And the mould was drilled for a probe.

The mould was preheated on a electric hot plate

Preheated mould to about 280F and cast one pour.

Discarded first pour.

Cast two more pour’s at 280F to 295F

The ten measurements are from that 2 pours

Returned mould to hot plate and repeated at 340FThis mould made great bullets at 280F to 295F

Very good fill out – nice clean casting!

At 340F to 360F bullets frosted but still had good fill out.It was interesting to see verification that hotter moulds do produce

smaller bullets and with this big bullet it was very apparent

Not the most scientific set up but I found out what I needed with it.Now it would be interesting to see if it was the mould block that produced

a smaller bullet or if it was more to do with the melt. Both pours with 700F

material makes you think! Still a lot to learnBullet maker, maker

Al Nelson2014-06-20 at 17:47 #491228daveridenour

Participant2014-06-20 at 19:25 #491229petergallo

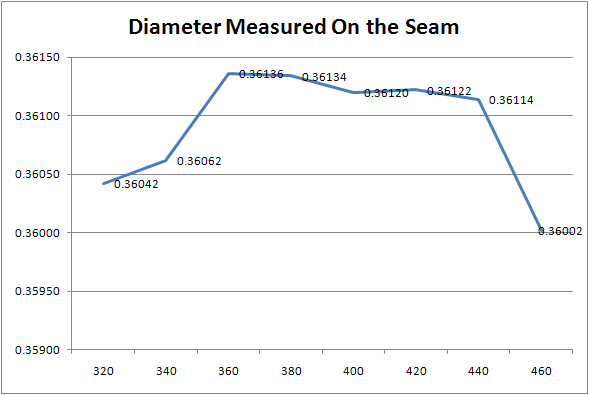

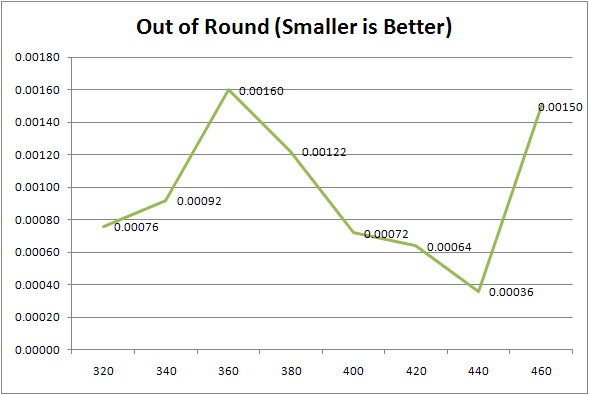

::I did a test on this a few years ago. The results indicated that size and roundness increased as the mold became hotter. Once the bullets started frosting the bullets started to be smaller again.

So, just shy of frosting works best. When I get it right, they don’t look frosted when they drop, but a few hours later they aren’t so pretty looking anymore.

For 357 magnum bullets the mold temps were about 420 for the best results, hotter than what Al and others posted. That was with range lead, BHN 8.

Added later: I checked my notes, and 360 degrees gave the biggest diameter on the seam. However the most round big bullet was at 420. That was using 2 measurements per bullet. One on the seam, one across the seam.

2014-06-26 at 23:43 #491230cliftonmorris

2014-06-27 at 10:20 #491231petergallo

::Sounds like you might be in the sweet spot, or maybe just a little hot. Does the nose look blemished the next day?

I’m assuming that you are talking the bands are lightly frosted. Casting rate is one of the big controls for mold temp, the other is the temp of the alloy in the pot. This concept is a little controversial and gets some folks wound up, but it’s true nonetheless. To keep cast fast and lower the mold temp you can try lowering the pot temp.

However, you are right there in getting max size and max roundness.

What temp are you using and what is the alloy?

2014-06-27 at 18:10 #491232robertpedersen1

::I had a certain, other, Utah-based custom mold maker cut me a 1-cavity brass mold for my own .44 cal. 437 gr bore-rider bullet.

It took failure of three molds to produce the desired diameters, for him to realize that all of his mold expansion formulas had only been tested with small caliber bullets of moderate or short lengths. He had never actually tested large, long, heavy bullets; and that oversight bit him. He had alloy shrinkage nailed down for a wide range of alloys and temperatures, but forgot to test brass molds with big bullets.But, even with the final mold that he cut after some more testing and the development of a formula specifically for large bullets in brass molds, he missed the target by 0.0015″ (out of tolerance); because he also never factored in the stresses in the brass for large bullets. Straight out of the lathe, the mold blocks were warped. (Something he, to this day, blames on customers “overheating” his brass molds…)

The mold gets the job done, but I have to run it hot (lightly frosting bullets) to keep the bore-riding nose at a usable diameter.

And, I have almost half a dozen different variations of NOE 314316 molds. They don’t have problems, but I use temperature to my advantage with them. One of the molds has a GCFP cavity that drops at only 0.313″. That’s perfectly usable in my revolvers, but if I run the mold hot (lightly frosted bases), the bullets don’t have to be sized down quite as far for use in .30-30 plinking loads.

And, there’s another 314316 that drops on the high side. If I run the mold as cold as possible, while still getting good fill-out, I can get the bullets to drop at 0.3163″ for use as-cast in my .315″-grooved Mosin-Nagant.Bottom line…

There are a lot of factors that come into play. For some bullets, mold temperature doesn’t affect the finished product by enough to matter to most casters. But when you have critical dimensions, achieving the proper mold temperature can be the difference between a usable bullet and a bunch of wasted time.

And, knowing how your mold reacts to different temperatures can let you ‘stretch’ it into doing things it otherwise may not be capable of achieving.2014-06-27 at 19:01 #491233SwedeNelson

Keymaster::357 shooter, Squigie

Great information, thanks for the input

What I have got out of all this is that if you’re not getting what you want

you have some options to get there. Work with your mould and you can

make it do some very interesting things.

Would be inclined to think that melt temp. has to do as much with it as block temp.Now I do need to try it with brass!

Not trying to explain it all just observations.

Had more fun with a thermometer and a hot plate than I ever thought I would!Try it and see what you get.

Bullet maker, maker

Swede Nelson2014-06-28 at 18:47 #491234erikdorothy

Participant2014-06-28 at 19:38 #491235robertpedersen1

::I’ve got to figure the cavities are shrinking as the metal of the mold heats up and expands.

Which leads me to guess that the largest possible diameters would come from cooler molds (larger cavities) and hotter pots (best fillout due to longer period to returning to solid)

It depends on the mold design and the mold material. Some molds will have the cavities expand as they’re heated, while others will have the cavities contract. How the molds react depends on many factors, including how the raw stock was made (extrusion, cold-rolling, hot-rolling, casting, etc), how the mold was cut (with the ‘grain’, across the ‘grain’, etc.), and on down the line. Something to keep in mind about that, is that the expansion rate usually results in a cavity that is not concentric. So you may get a bullet that is 7 ten thousands larger than typical, in one direction, but it could also be smaller than typical when measured 90 degrees off.

And… your alloy temperature can have an affect, as well. The hotter the alloy, the more shrinkage there will be when it cools. The harder the alloy is (the higher then antimonial content), the more pronounced the effect will be.

If you’re running a really hot alloy in relatively cool molds, there’s also the issue of ‘hot spotting’. You can have one mold block notably hotter than the other, hot spots in both mold blocks, or just a really hot nose or base. Any of those conditions can cause localized abnormalities.2014-06-29 at 11:06 #491236petergallo

::I’ve got to figure the cavities are shrinking as the metal of the mold heats up and expands.

Which leads me to guess that the largest possible diameters would come from cooler molds (larger cavities) and hotter pots (best fillout due to longer period to returning to solid)

Back in reply #6 I posted the testing result and temp from aluminum molds. I also tested iron (ran slightly cooler), but no brass molds. For both alum and iron, the largest bullets come from a mold that is just shy of frosting. The pot temp didn’t seem to matter much except that it, along with cadence, helps keep the mold temp even.

The bullets actually start with a larger diameter along the seam compared to across it, and become more round as they heat up. Once you cross that point where they drop frosted they start shrinking again.

I would assume brass would work the same way. But that’s pure speculation on my part.

Below are charts of the mold temp and the diameter for the aluminum molds. This is with BHN 8, which requires a hotter mold to cast full size bullets, so you may need a cooler mold. I found that 400-410 was a good temp for my casting with my alloy:

The diameters measured on the seam (big is best):

The diameters measured across the seam (big is best):

The amount “out of round” (small is best):

2014-06-30 at 18:47 #4912372014-06-30 at 23:52 #491238

2014-06-30 at 18:47 #4912372014-06-30 at 23:52 #491238petergallo

::Those measurements came from a Lee 6 cavity. The temps were different with NOE, Lyman and RCBS but the overall end result was the same. The bullet gets more round and drops at it’s largest size with the mold temp just shy of frosting.

I did find that casting at a full cadence worked best with slight lower temp, again just shy of frosting. It’s the difference of doing a test vs how things work in production mode.

2014-07-01 at 00:49 #491239cliftonmorris

::@357, sorry I’m tardy getting back to check on my question. I was casting 240gr .44 Keith Type bullets from an old RCBS 2 cavity mould. The nose was flat silver after the drop while the body containing the driving bands and grease groove looked crystalline on the surface after the bullet cooled you could see a trace of the crystal structure on the nose of some. I was still not getting good consistent fill at the plain base which is what I was trying to deal with. I surfaced the sprue cutter and used a sharp graving tool to open the air escape channels a tiny bit but still no joy. I’ve tried ladle pouring and bottom pouring with all sorts of varIations in flow and pour height. Still get some rounded off bases. I try to keep my pot temp at 680-750 but that brings me to the subject of pot thermometer accuracy at various levels. I’m pretty well convinced they there is significant error in the thermometer since it may be reading over 700 and the lead is still pooling up on top of the spruce plate and solidifying fairly quickly. Other times the lead wants to run right off the plate yet the gauge says it’s at the same temp. I have not used a mould thermometer yet but it is in the planning. This one mould seems to be problematic.

-

AuthorReplies

- You must be logged in to reply to this topic.