Home › Forums › NOE Forums › NOE Archive › Historical Archive › Using NOE Moulds › At the Range › 30 XCB testing continues

- This topic is empty.

-

CreatorTopic

-

2014-11-25 at 17:30 #487724

bjornborud

Participant::As I’m getting some ammo ready for my 30 XCB rifle, I’d like to share this contraption, fabricated by Goodsteel: It’s a guided breech seater, made to fit the front and rear rings of a large ring Mauser. The idea is to seat the bullet (we’re talking about the NOE 310-165 XCB bullet) until it fully engraves, i.e. all the way to the gas check.

-

CreatorTopic

-

AuthorReplies

-

2014-11-25 at 19:36 #494204

sgt.mike

2014-11-26 at 18:51 #494205darrinwright

2014-11-27 at 00:58 #494206bjornborud

Participant2014-11-27 at 01:34 #4942072014-11-27 at 01:51 #494208bjornborud

Participant::I finally was able to take Bertha, my 30XCB rifle, to the range for the first time after her rebarreling.

The rifle has a 30 inch Shilen Match barrel with a 1:14 twist, installed by Tim Malcolm aka Goodsteel. Tim also re-bedded the rifle action and the first 6 inches of the barrel.

I loaded up some jacketed rounds to test the accuracy of the rifle, and after getting on paper she shot these 5 rounds at 50 yards:

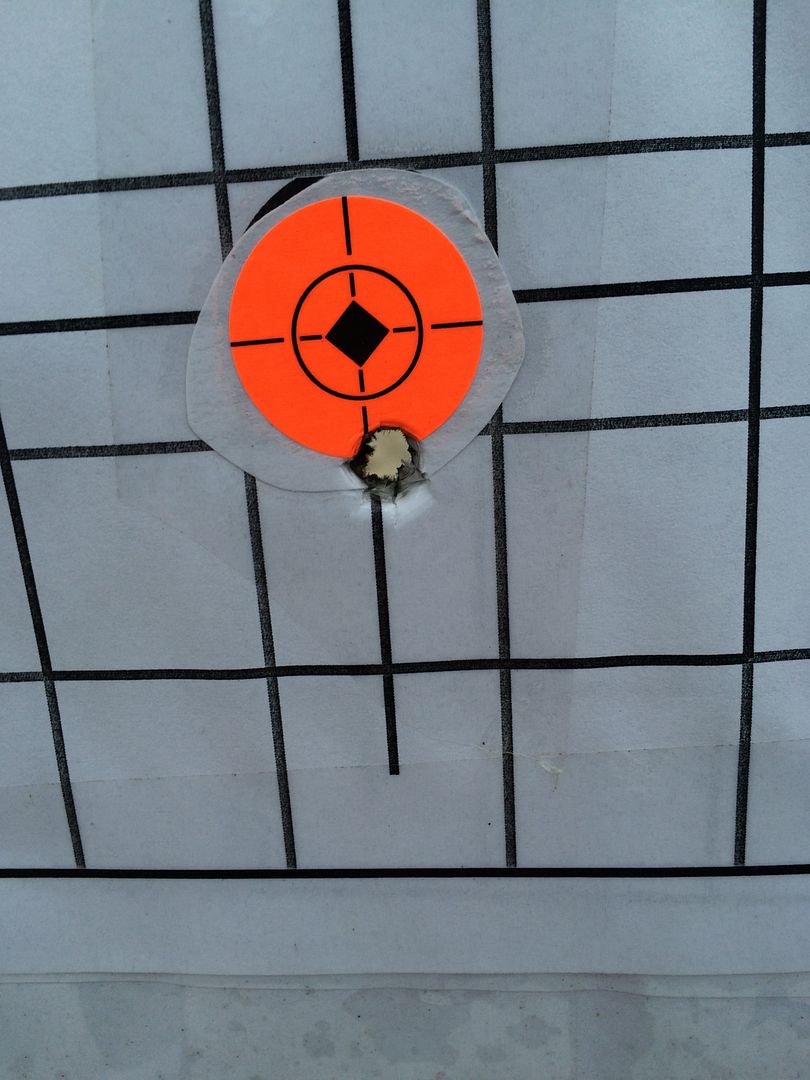

At that point I moved the target to 100 yards, and the rifle continued to impress:

2014-11-27 at 03:16 #494209

2014-11-27 at 03:16 #494209bjornborud

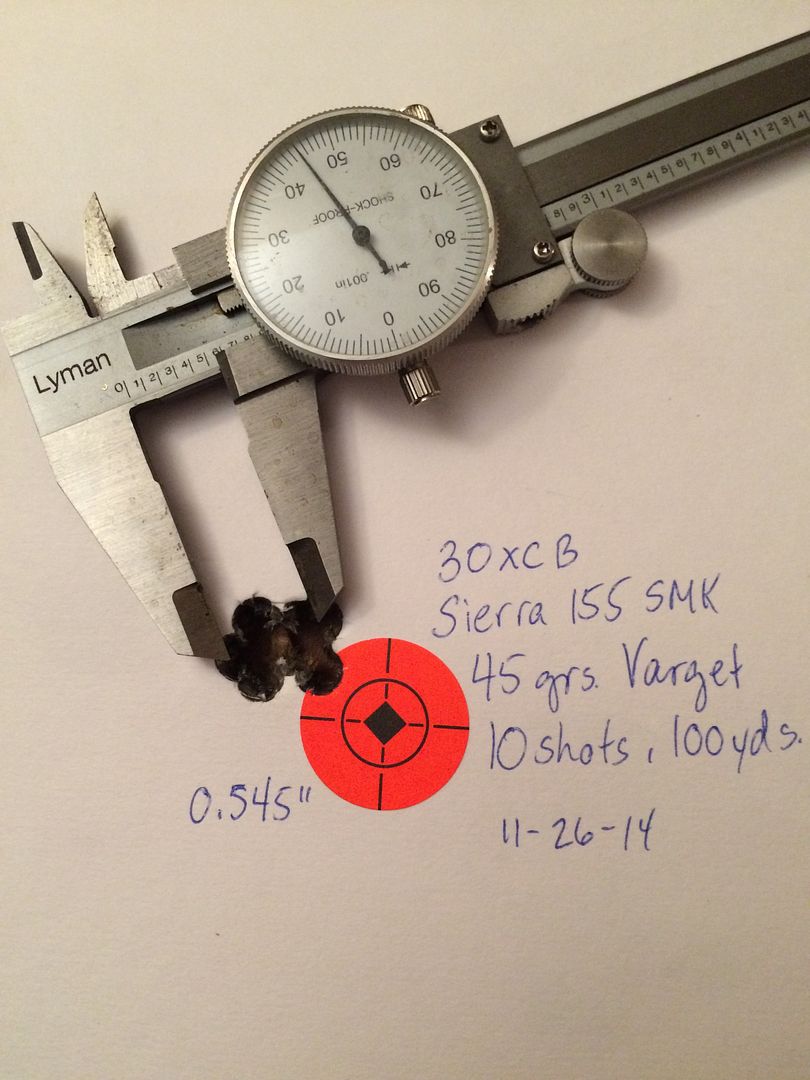

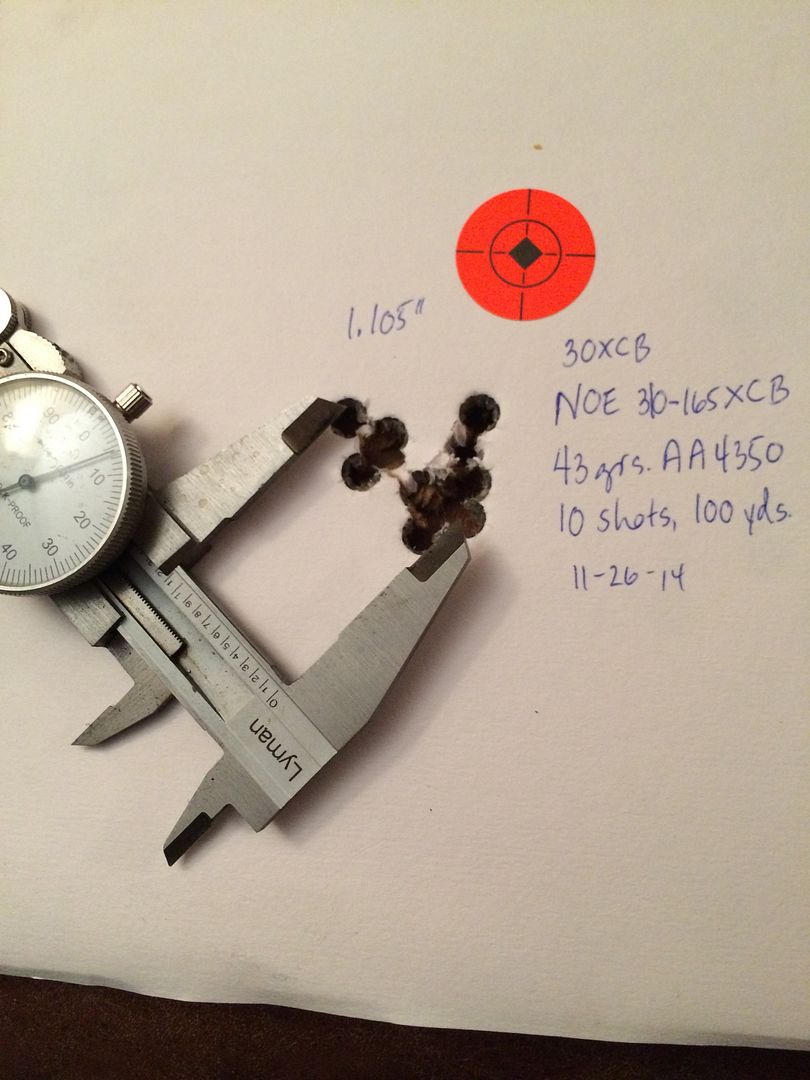

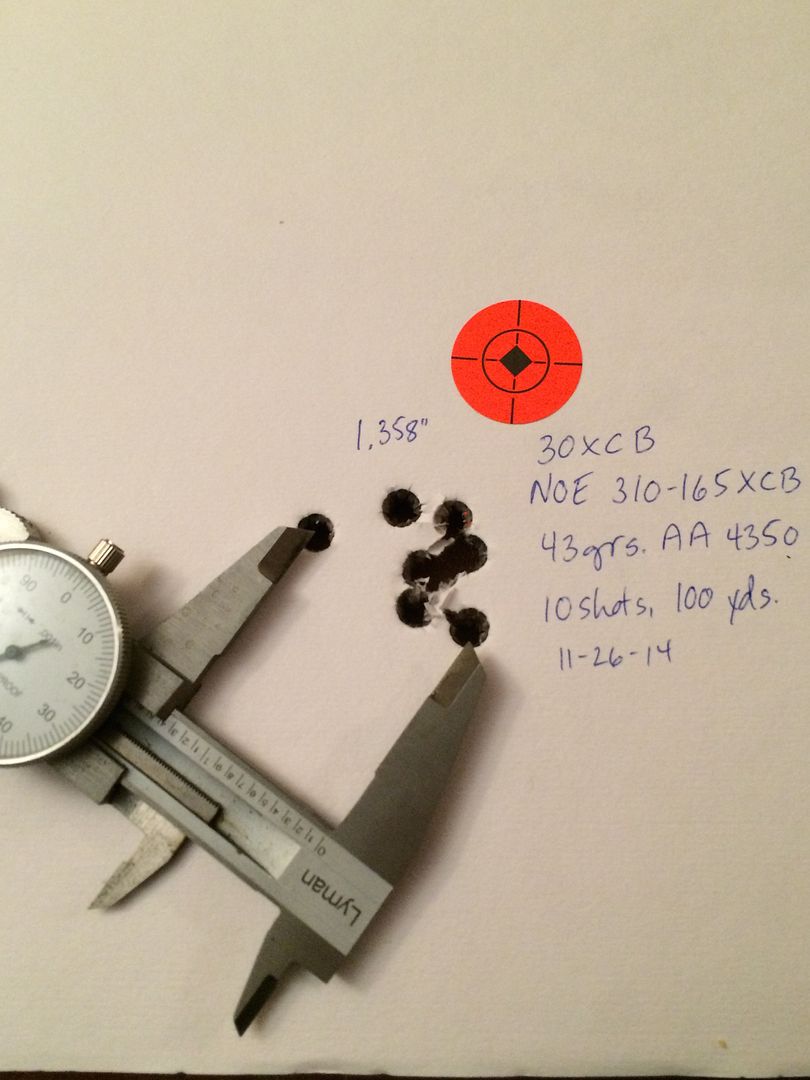

Participant::I had brought along 25 rounds loaded with the NOE 310-165 XCB bullet, all over 43 grains of AA4350. No chronograph was used today, but previous shooting has clocked this load right at 2400 fps with the old 27″ barrel, so I had a pretty good idea about the MV. I’ll show the two 10-shot groups here:

I’m posting these results as a start/baseline, as I will be attempting to shoot this bullet at velocities in the 2700-2800 fps range in the coming weeks. Different powders and alloys will be tried, as well as a lube or two. Stay tuned.

2014-11-27 at 04:19 #4942102014-11-27 at 05:00 #4942112014-11-27 at 10:27 #494212timmalcolm

::I’ll be testing the MBT breech seater today hopefully. Going out to have turkey with the Larson’s (White Label Lubes) and I think Glen will get a kick out of this.

Sgt.Mike and I were messing with it in the shop last night, and you can easily push a 27 BHN bullet into the barrel completely with ease, and it’s absolutely perfectly aligned through the entire process.

I could actually see using this tool on the bench, and it wont slow the loading process down much at all.

The object of the breech seater is to eliminate the bullet engraving pressure that Larry Gibson demonstrated with his lab. The thought is, that either the damage to the bullet is happening there, or the bullets are simply not balanced enough as they drop from the mold. By seating the bullet in the rifling fully, with minimal damage, I believe the highest possible speed will be realized. I am very curious how much the RPMTH will be pushed up with this method. Curiosity is killing me, especially with the ten twist.Bjorn, excellent shooting! A new barrel is absolutely the best place you can put your money followed closely by a bullet mold that matches your rifle perfectly.

I am very interested to see what you can accomplish now that you have true precision at your beck and call on several different levels.BTW, I love the fire star you get on that barrel. Each one is like a snowflake, and I observe because you can tell if the crown is square by the look of that pattern:

Ya just can’t ask for better than that!2014-11-27 at 16:22 #494213Larry Gibson

::Definitely an outstanding start Bjorn has with his new rifle, the 30 XCB cartridge and the NOE 30 XCB bullet. Bjorn is going to ship Tin’s bullet seater to me to test. I will test both in the Palma .308W that I posted results on the other thread here. I also will test in my 30×60 in a Broughton 16″ twist barrel on a BRNO VZ24 action that Tim is putting together. The testing will be to see if and how much the breach seated bullet moderates the initial pressure when the bullet enters the leade.

I also have been testing a new NOE expander plug made for use with the Lee case mouth expander die. So far it is proving excellent and it promises a lot of potential to have several different sized for varying the neck tension with cast bullets. I will have a write up with pictures soon as I am solidly wrapped upped in Thanksgiving “honey do’s” right now……oh, oh….I got caught…….the boss is calling …….got to go….great start Bjorn…..Happy Thanksgiving to all…..

Larry Gibson

2014-11-27 at 16:44 #494214timmalcolm

::I am hopeful that the engraving pressure blip that all your pressure traces produce (you can see the pressure spike just a little as the bullet is engraved) will be greatly reduced or even eliminated by this tool. The thought is that if the bullet is not receiving damage nor getting started in a peculiar way at launch we might be able to modify the RPMTH to the point that we can achieve jacketed velocities/RPM with cast. Its just a theory, but that’s what I built the tool to shed light on.

Today, I am taking my XCB rifle out and I will be using this tool for the first time. I have loaded up a bunch of brass with stout charges of 4895 that I hope will produce speeds in the 2400-2700 FPS range.

My rifle wears a 10 twist barrel, so this is obviously waaaaaay over the RPMTH for this twist. If it works, then bully. If not, then I will take the 10 twist off the rifle and never look back.

At least this method insures absolute perfection at launch (or simulates it).

The bullets are made of heat treated alloy that is 27 BHN IIRC (this will be verified later). I have a sampling that is lubed with Lars 2500+ and 2700+. We shall see what happens.2014-11-27 at 19:03 #4942152014-11-28 at 05:01 #494216Rockrat

Participant2014-11-28 at 14:53 #494217swheeler

2014-11-29 at 02:16 #494218timmalcolm

::The Mauser action has a 5/16″ square protrusion with a slot through it that the boltstop hinges on, and a .120 diameter hole going down through it to hold the boltstop in place. I used the same method to hold the breach seater block, except I extended it out the rear of the action. In the same manner that the screw held the bolt stop in place in the original design, the screw through the breach seater serves the same purpose. It does nothing but hold the block in place tight against the action. When the bullet is being seated, all the pressure is being exerted on the 5/16″ slotted protrusion.

I took the seater out with Glenn Larson of White Label Lubes. The charge of 43.5gr of IMR 4895 produced 2300FPS (roughly). The shots sprayed the target in about a 3′ diameter group/pattern with 2500+ lube.

When we switched to 2700+, the groups shrank considerably. We had several three shot groups that were close to an inch in diameter and we thought we might be on to something, but then the next few shots opened the group to about 12″. As it was, even though we got several shots that seemed to try to group, taking the entire cone of dispersion into consideration, I have to call it a 12″ group.

In previous outings, seating the bullets normally with these same lubes and powder, no sub 2MOA group was able to be shot over 1950FPS average.

Obviously, this test was very inconclusive as far as bullet performance goes, but that was not the main objective for this demonstration. What I was mainly concerned with determining was how well the seater would hold up to normal use in a shooting environment. All things considered, I was very impressed by the ease of use, and the functioning of this tool. A total of three gentlemen used it and then fired the rifle with no issues, two of whom had never laid eyes on it before, and there was not one single hiccup in it’s performance during this outing.

I feel good about sending this to Bjorn for more thorough testing. -

AuthorReplies

- You must be logged in to reply to this topic.